Problems with the glue used to mount tips to foam on cheap bulk darts such as waffle, accutip/whirlwind, etc. are familiar in the hobby, as are seeing darts decapitated on firing, darts exploding on impact with hard targets, and finding handfuls of disassembled dart components on a field during sweeps. Those of us who have been around more than a few years have been lamenting and lambasting dart assembly quality for probably their whole nerfing career. Even these days, with better glued options on the market, waffle and accutip continue to be staples of most any field and can be normally observed in action (decaps included) at anything from a small local HvZ to a league-aligned comp match.

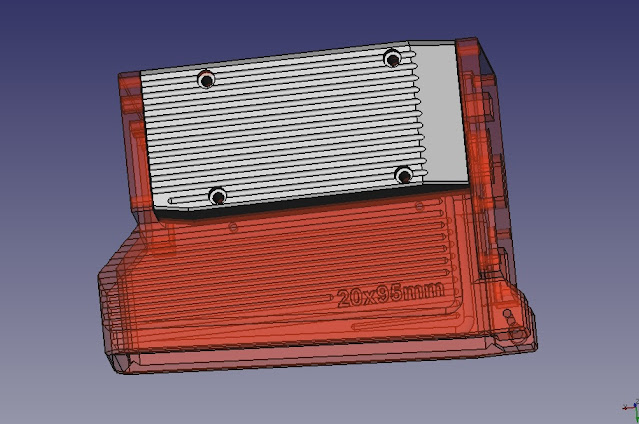

For some background, this disassembled accutip dart is typical of how all the "usual suspect" Chinese vendors assemble darts:

Problem zero is that this is CA glue - which is NOT the right product to assemble darts with. It is far too rigid when cured, and makes for a brittle bond. Although the CA itself may not break or debond from the foam or rubber, its inflexibility causes the joint to be unable to redistribute stress, and the foam just adjacent to the glue rips easily. CA also wicks into the cell structure of foam, which has the effect (after curing) of making the foam crunchy and brittle adjacent to the bond when it is used on the cut end.

Problem one is that adhesive is applied only (and usually very sparingly) to the tip core, and none to the rear surface of the tip where it seats on the foam end. This is the elephant in the room here, some readers may know why. For now though, here's an example that barely had any bond area at all.

And hence, the old flywheeler's vexation, decaps.

For much of the superstock/onward era (2012-present, more or less), these dodgy CA-glued darts have been just a given we all had to contend with, and something we designed around - based on the prevalence of these darts, in stock, un-reglued form, for community bins and private supplies as the thing that enabled the entire hobby to scale up in game size and volume of fire in the first place. The measure of true merit for any flywheel system was how much energy it could put out without being too brutal on darts to be welcome to feed off a community bin. That, incidentally, underlied the Hy-Con of the era, and consequently (and directly as well) Daybreak, a system that somewhat spiritually succeeded Eclipse, which was somewhat maligned and targeted by bans in its day for how harsh it was on ammo.

More recently but still years AKA eons ago in nerf time, some more tightly hobby-aligned, vertically integrated dart vendors stepped up to the plate on the glue matter with properly glued hobby darts using elastomeric adhesives just like Hasbro. Mostly... that's Prime Time (DZP/AF). A lot of nerfers have probably just dumped bulk darts and changed suppliers to Prime Time, Worker et al., and hence are now wondering why I am posting about a problem that is in the past.

Well, the lesson to be learned is not in the past. Neither are the darts, necessarily; but we'll get to that.

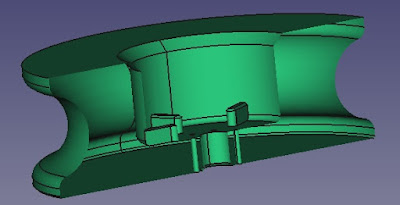

A look at what is going on with these "glue on core only" assembly jobs:

Yeah that seems like it would make for awesome flywheeler internal ballistics, right...

It's not like this is new knowledge at all - dart tips that aren't glued to the end face to the foam have been known to cause flywheel blasters issues ever since the era of clone Streamlines and later, ACC darts.

It's just that up to this point, it has been assumed that this isn't a major problem for tips like the waffle, the accutip, the Sureshot, the Mengun, the brick/stagger tip, and so on. They still shoot fine, right. Right.

Mostly.

Well, I was chasing 2 issues. One, at the last game I played, I had a lot of ...questionable ballistics. My full length 9.0 rigs with these offending darts incidentally did about the same on range, drop and group size when fired side by side with other flywheelers at the event using the ammo their owners fed them (Banned Blasters flywheels Gryphon, one of those beta Gavinfuzzy SBF things, full length and short FDL3 builds, etc.) but still I could tell something was Not Right and they were just shooting kinda dirty and under the weather. There wasn't a chrono onsite so I couldn't ascertain what velocity was doing under site conditions, but I was spamming at people I should have picked right off. I chalked it up to imagination, or me being mad rusty after being on hiatus for a while, or that using black darts was a terrible idea that makes it harder to see your "tracers" fly and compensate when there is any wind, but doubt remained that something untoward was going on with my setup that day.

Two, I was trying to use these pictured batch of black foam accutip darts in some chrono sessions with T19s for a project to be discussed later, and holy crap, they DO shoot like garbage and I was not imagining things. I had strings of dud shots down in the 140s, 150s, 160s from a 9.0 cage at 25k, stuff going sideways as soon as it cleared the muzzle, and ...well, my other 2 batches of waffles and accus misbehaved the same way. Swapped blasters: Same results. What on earth is going on???

Granted, the weather during all of the above was typically 90-96 degrees Fahrenheit, near 100% humidity, and that may well be WHY this started manifesting so severely after having eluded notice for so long (part of it is also that I never actually used non-reglued bulks as a chrono or ballistic testing standard because of the decap rate expected of such darts, which was a problem I was willing to accept for the cost), but this brought to light the magnitude of this problem.

That problem.

In the end, I got my data. I disassembled the problem darts, reglued them with Plumber's Goop (Amazing Goop, whatever Goop, all the same stuff, all a great dart adhesive and similar to what the first rate vendors use), let cure, and what do you know, they shoot lasers. Velocity was back up to nominal (hanging just under 190fps on an old 9.5 gun), the velocity spread was somewhere around +/-3 fps typical - might note, with reused darts too - and there was zero doubt in my mind about how those two 9.0 blasters were running anymore once I fed them some.

Conclusion

It's not just decaps that are at stake with dodgy assembly of darts, as everyone (including me) tended to think for years. It does, or at least can with the wrong batch of darts and conditions, seriously screw with the internal ballistics of flywheel blasters whether or not any tips come off at all.

The old wisdom from the "ACCurate" dart + Rapidstrike = squib/fail observations (where simply regluing the dart removes the problem, as if by magic) still holds. It holds even for full-caliber tips, like waffles and accutips. The tip needs to have a moment connection to the foam.

That is what it is - A moment connection. You can tell instantly by just touching/feeling the reglued dart - bonding that region makes the whole front of the dart much sturdier and stiffer. Glue on just the core is not that. The compound used to make rubber tips is very elastic, and the tip is basically held on by a rubberband and can flap about loosely, for blasting purposes. Likely, the tip is tilting due to an imbalance of initial friction forces for whatever unavoidable reason, being forced through the rest of the contact zone at an angle, and then getting wedged into the control bore wall incurring severe losses - but I would need high speed video equipment to catch the failure mechanism in the act.

Ramifications

Well, for one thing, bulk darts that haven't been reglued are never getting fielded by me again. It's at this point that I realize that in a lot of everyday game scenarios where I choose cheap darts to burn (for not wanting to use any of my reglued, handpicked or expensive good stuff) I have likely been at least intermittently down on performance, in addition to just chopping frequently.

For another, this all with realizing these to be basically unfit for purpose has exposed the fact that designing flywheel systems around not "instakilling" non-reglued bulk darts of this sort, the kind with a tiny smidge of superglue on just the core ...is a legacy idea that is very much no longer relevant to modern NIC. "Why not more crush?" Well, why not more crush? I think I'll experiment with more crush.

Are bulk darts obsolete? I wouldn't say so, at all. It would be different if the same products were available with better glue, but Prime Time's two Sureshot tips are not (pending testing/data on the green tip/red foam dart, that I have coming to do just that) quite heavy enough to be a true range-maintaining replacement for waffle and accustrike. The blue tip Sureshot (1.0g) is definitely just not heavy enough and too droppy for outdoor work. Same, incidentally, with most of the sub-caliber springer tips, which are also expensive and have given me some questionable results concerning inaccuracy of reused darts, high foam wear rate on flywheel and other factors.